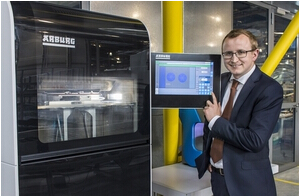

Krause: freedom in design

Igus, a German manufacturer of energy chain systems and bearings made from plastic, is using Arburg’s Freeformer to produce functional parts and prototypes from standard granulates.

Tom Krause, product manager at Igus, says: “The Freeformer allows us to use our own high-performance plastics for prototypes and functional parts. It means we are now able to combine freedom in design with the wear-resistant properties of our tribological materials.”

Of the more than 40 special materials that Igus uses, three are specially designed for additive manufacturing

With the Freeformer it is possible in principle to process the same plastics as in injection moulding.

The materials first have to be qualified to ensure that this can work smoothly. Qualification calls for the precise adaptation of parameters such as temperature, droplet discharge or layer thickness to the specific properties of the material.

Krause says: “The Freeformer currently mainly processes iglidur I180 which is suitable for industrial applications and uses this to produce parts such as bearings, grippers and gearwheels in an additive manufacturing process. Our tests showed that this material is around 50 times more resistant to wear than conventional ABS for 3D printing”

In the test laboratory, a bearing made from the injection moulding material iglidur J260 in an additive manufacturing process was found to be just as wear-resistant as an injection-moulded part made from the same material.

In general, additive manufacturing offers significantly more freedom in geometric design than injection moulding. When it comes to the development of new products directly from 3D CAD data, changes in design can be implemented immediately, so that the next generation of the prototype or design sample, or an ongoing product can be quickly produced without requiring a mould.

Krause says this is the ideal way to test a new product in practice before it is moulded in large quantities and produce replacement parts. Igus has now taken things one step further and now offers its own 3D printing service.

Krause: freedom in design

Igus, a German manufacturer of energy chain systems and bearings made from plastic, is using Arburg’s Freeformer to produce functional parts and prototypes from standard granulates.

Tom Krause, product manager at Igus, says: “The Freeformer allows us to use our own high-performance plastics for prototypes and functional parts. It means we are now able to combine freedom in design with the wear-resistant properties of our tribological materials.”

Of the more than 40 special materials that Igus uses, three are specially designed for additive manufacturing

With the Freeformer it is possible in principle to process the same plastics as in injection moulding.

The materials first have to be qualified to ensure that this can work smoothly. Qualification calls for the precise adaptation of parameters such as temperature, droplet discharge or layer thickness to the specific properties of the material.

Krause says: “The Freeformer currently mainly processes iglidur I180 which is suitable for industrial applications and uses this to produce parts such as bearings, grippers and gearwheels in an additive manufacturing process. Our tests showed that this material is around 50 times more resistant to wear than conventional ABS for 3D printing”

In the test laboratory, a bearing made from the injection moulding material iglidur J260 in an additive manufacturing process was found to be just as wear-resistant as an injection-moulded part made from the same material.

In general, additive manufacturing offers significantly more freedom in geometric design than injection moulding. When it comes to the development of new products directly from 3D CAD data, changes in design can be implemented immediately, so that the next generation of the prototype or design sample, or an ongoing product can be quickly produced without requiring a mould.

Krause says this is the ideal way to test a new product in practice before it is moulded in large quantities and produce replacement parts. Igus has now taken things one step further and now offers its own 3D printing service.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site