For replacement of steel machine parts

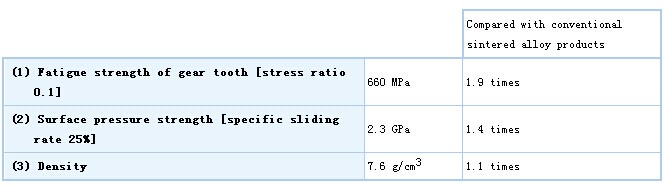

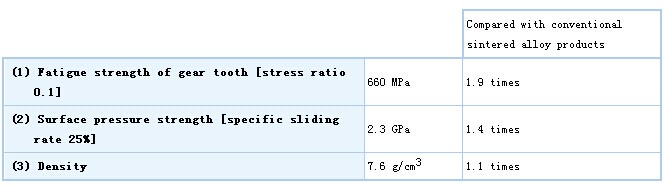

NTN Corporation (hereafter, NTN) has developed a high-strength sintered alloy with a density of 7.6 g/cm3 or more and an endurance strength*1 of 660 MPa*2 (maximum stress 1467 MPa) or higher. This allows machine parts that require cutting processes, such as gears and bushes to be replaced with sintered alloys, which until now had a limited range of applications.

Sintered alloys are used in the automotive and other fields as they allow parts with complex shapes to be produced in high volumes and low cost, without the need for any cutting work. Conventional products made of sintered alloys (hereafter, conventional sintered alloy products) have pores throughout their structure. This results in inferior reliability and fatigue characteristics compared to components manufactured using cutting process of solid metals (hereafter, ordinary steel parts), which limited their scope of applications.

NTN developed a high-density sintered alloy in 2012, and conducted further research to optimize the base powder, molding, heat treatment and other processes with the aim of achieving a higher density and strength.

The use of a proprietary heat treatment process has improved the fatigue strength of gear tooth to 660 MPa, which is almost double that of NTN's conventional sintered alloy products and similar to ordinary steel parts. This allows many types of machine parts to be replaced with this developed product, which was not possible with conventional sintered alloy products. A surface pressure strength, the index for surface stress on gears faces, of 2.3 GPa*3 or more has been achieved.

NTN will not only apply this developed product to machine parts, but also units and module products that feature combinations of resin parts and magnetic parts that NTN has core technologies. The product will also contribute to lower fuel consumption and electrification of automobiles, as well as enhance the reliability of industrial machinery components as part of efforts to achieve a reduction in environmental impact.

larger stresses result in failure after fewer cycles, and the number of cycles that result in failure increases as the stress decreases. Failure might never occur in some materials when the stress is below a certain value, and the value of this maximum stress amplitude is called the endurance strength, endurance limit or fatigue limit.

By gear profile bending test method (stress ratio 0.1).

The maximum stress value achieved without flaking between two cylindrical test specimens when the outer diameters are pressed together and rotated with a difference in speed to cause slipping relative to the other test specimen.

Features

Applications

Gears, cams, bushes and other machine parts

Product photo

Applications

Gears, cams, bushes and other machine parts

Product photo

Applications

Gears, cams, bushes and other machine parts

Product photo

Mobile Site

Mobile Site