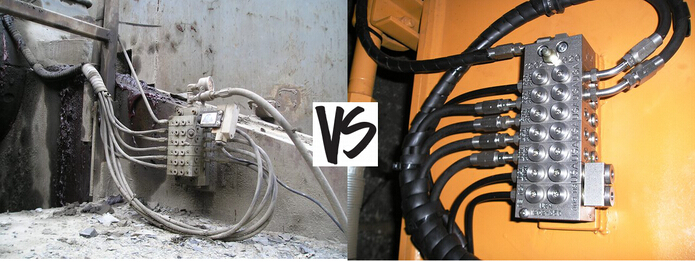

An effective lubrication system can dramatically improve plant performance - image courtesy of Lubrication Scientifics.

Corrosive plant environments are one of the most common contributors to extensive production downtime and exorbitant maintenance costs.

According to a G2MT Laboratories report, the annual cost of corrosion for the US industrial market was expected to reach over $500bn in 2015. This estimate is based on the most recent NACE (National Association of Corrosion Engineers) study, adjusted for inflation.

Among the most devastating effects of corrosion is its destructive impact on the load bearing surfaces of plant equipment, which are supported by many types of bearing components such as rollers, spines, gears, ball bearings or other moving parts. Unless these components are provided proper lubrication, they will be subjected to excessive heat and wear, both leading to premature failure.

With today’s equipment running at higher speeds and longer periods, it is more important than ever to ensure that lubrication systems are providing bearing devices with efficient, timely applications of lubricating oil or grease in order to ensure wear life, safe operation, reduced unscheduled downtime of processing machinery, and more economical operating costs. For that reason many manufacturers are opting for automating their lubrication systems.

The multi-point challenge

Many food and beverage manufacturing operations have hundreds, even thousands of lubrication points in a single facility. Although automatic lubrication systems have been around for decades, much of this work is still conducted using manual labor – particularly when the lubricant is grease.

While the food and beverage industry is manifestly moving to higher-speed, higher-volume automated equipment, it is becoming increasingly impractical for the industry to depend on labor-intensive, point-by-point, manual grease gun lubrication on a timely basis.

“Bearing giant SKF has estimated that 57 percent of all bearing failures are lubrication-related,” explains Richard Hanley, president of Lubrication Scientifics, LLC (Irvine, CA). “That rate can be reduced dramatically by automating the lubrication process, which ensures that the right amount and type of lubrication are delivered to every equipment bearing point.”

Lubrication Scientifics engineers and manufactures have a variety of automated lubrication systems and components that are installed on equipment used in a wide variety of industries in addition to food processing, including the pulp & paper, chemical processing, steel, petrochemical and mining industries.

From an economic point of view, for most of these systems the payback period is less than a year. In some cases, engineered lubrication systems with advanced monitoring capabilities can easily save elaborate processes such as brewing operations millions of dollars in downtime costs per year.

Automated lubrication systems eliminate the cost and sometimes-hazardous task of manually applying controlled amounts of lubricant to multiple equipment locations at frequent time intervals while the equipment is operating.

“More frequent delivery of smaller amounts of lubricant is particularly important to bearing points on high-speed equipment,” Hanley says. “This prevents overheating the bearings due to excessive lubricant buildup, and ensures longer operating life.”

Harsh food processing environments

Food processing plants are exposed to some of the harshest environmental factors, including extreme room temperatures and mandatory wash-down procedures that may occur at frequent intervals.

FDA, 21CFR110.35 requires that all processing lines and equipment be adequately sanitized, as often as necessary. This requirement is typically met by a full equipment wash down, with an approved cleaning agent. These wash-downs create serious corrosion problems for any non-stainless steel components used in the processing line.

Corrosive damage from exposure to caustic wash-down fluids can severely compromise the performance and service life of lubricating system metering valves – the valves that dispense oil or grease in controlled proportions to each connected lube point – which are constructed of zinc- or nickel-plated carbon steel.

“In such an environment, the corrosion resistant life of a plated carbon steel metering valve or system component will only be weeks to months,” Hanley says. “Although the initial corrosion will look much like rust, it will eventually cause the lubrication metering valve to lose its effectiveness long before normal wear and tear would compromise that part.”

In the food processing industry, corrosion problems are normally prevented through the use of equipment made of stainless steel. However, as a broad offering of stainless steel metering valves has not been readily unavailable, the only effective anti-corrosion solution for automatic lubrication system components has been to enclose the plated carbon steel metering valves into stainless steel enclosures. Including the cost of the enclosure, the bulkhead fittings, and the installation labor, it is easy to spend $2,000 to protect a $500 plated carbon steel metering valve. Yet, the space required to mount such as enclosure may not be available on or near the processing line.

In such cases the installation metering devices made of stainless steel that can be mounted directly to the plant equipment is the most cost effective solution to maintaining sanitary standards and insuring long-term production reliability. Typically, stainless steel metering valves such as those offered by Lubrication Scientifics cost between 1-1/2 and 3 times the price of a carbon steel-plated metering valve. Still, this is typically 40% to 60% less expensive than enclosing plated carbon steel valves in a stainless steel enclosure.

Lubrication part of automated system basics

There are several different types of automated lubrication systems, but a typical system consists of controller/timer, pump with reservoir, supply line, metering valves and feed lines.

Whatever the design, automated lubrication system metering valves must stand up to the rigors of harsh plant environments.

One of the most common lubrication systems is the Single-Line Parallel, which is also referred to as the Injector-type of lubrication delivery methodology. This system is known for its ease of installation, adjustable metering of valves (or injectors) and applicability to a minimum of one and maximum of six lube points per device. Lubrication points may be added or removed without redesign of the system. On the down side, it is difficult to verify that each lubrication point is constantly being serviced.

Another common system is the Dual-Line Parallel. This system is also easy to install and features adjustable metering valves. With this type of system a minimum of one and maximum of eight lube points may be serviced from each device, and lubrication points may be added or subtracted without system redesign. Also, heavy greases may be delivered over very long distances. However, with this system it is difficult to verify that each lubrication point is constantly being serviced.

A third type of automated system, the Single-Line Progressive System (aka the Divider Valve System), is precisely engineered to deliver exact lubricant requirements to each point. However, with this system lubrication amounts and points may not be altered, and initial installation costs are higher than with other systems. A primary advantage of these systems is that system performance can be easily and inexpensively monitored to verify that each lube point is constantly being serviced.

In order to overcome the various threats of corrosive and caustic environments, Lubrication Scientifics makes all three types of system and components available in 303 and 316 stainless steel, most of which are available within days rather than months.

Verifiable system advantages

Plants that have the verifiable automated system normally have the need to deliver precise amounts of lubrication to many points.

The biggest advantage of the Single-Line Progressive type of system is that every lubrication point is monitored, ensuring that each point is receiving the proper lubrication, thereby maximizing production uptime.

In addition, this type of system prevents unauthorized interference with system settings, so that workers cannot inadvertently change the precise amounts and intervals of lubrication sent to various points.

An effective lubrication system can dramatically improve plant performance - image courtesy of Lubrication Scientifics.

Corrosive plant environments are one of the most common contributors to extensive production downtime and exorbitant maintenance costs.

According to a G2MT Laboratories report, the annual cost of corrosion for the US industrial market was expected to reach over $500bn in 2015. This estimate is based on the most recent NACE (National Association of Corrosion Engineers) study, adjusted for inflation.

Among the most devastating effects of corrosion is its destructive impact on the load bearing surfaces of plant equipment, which are supported by many types of bearing components such as rollers, spines, gears, ball bearings or other moving parts. Unless these components are provided proper lubrication, they will be subjected to excessive heat and wear, both leading to premature failure.

With today’s equipment running at higher speeds and longer periods, it is more important than ever to ensure that lubrication systems are providing bearing devices with efficient, timely applications of lubricating oil or grease in order to ensure wear life, safe operation, reduced unscheduled downtime of processing machinery, and more economical operating costs. For that reason many manufacturers are opting for automating their lubrication systems.

The multi-point challenge

Many food and beverage manufacturing operations have hundreds, even thousands of lubrication points in a single facility. Although automatic lubrication systems have been around for decades, much of this work is still conducted using manual labor – particularly when the lubricant is grease.

While the food and beverage industry is manifestly moving to higher-speed, higher-volume automated equipment, it is becoming increasingly impractical for the industry to depend on labor-intensive, point-by-point, manual grease gun lubrication on a timely basis.

“Bearing giant SKF has estimated that 57 percent of all bearing failures are lubrication-related,” explains Richard Hanley, president of Lubrication Scientifics, LLC (Irvine, CA). “That rate can be reduced dramatically by automating the lubrication process, which ensures that the right amount and type of lubrication are delivered to every equipment bearing point.”

Lubrication Scientifics engineers and manufactures have a variety of automated lubrication systems and components that are installed on equipment used in a wide variety of industries in addition to food processing, including the pulp & paper, chemical processing, steel, petrochemical and mining industries.

From an economic point of view, for most of these systems the payback period is less than a year. In some cases, engineered lubrication systems with advanced monitoring capabilities can easily save elaborate processes such as brewing operations millions of dollars in downtime costs per year.

Automated lubrication systems eliminate the cost and sometimes-hazardous task of manually applying controlled amounts of lubricant to multiple equipment locations at frequent time intervals while the equipment is operating.

“More frequent delivery of smaller amounts of lubricant is particularly important to bearing points on high-speed equipment,” Hanley says. “This prevents overheating the bearings due to excessive lubricant buildup, and ensures longer operating life.”

Harsh food processing environments

Food processing plants are exposed to some of the harshest environmental factors, including extreme room temperatures and mandatory wash-down procedures that may occur at frequent intervals.

FDA, 21CFR110.35 requires that all processing lines and equipment be adequately sanitized, as often as necessary. This requirement is typically met by a full equipment wash down, with an approved cleaning agent. These wash-downs create serious corrosion problems for any non-stainless steel components used in the processing line.

Corrosive damage from exposure to caustic wash-down fluids can severely compromise the performance and service life of lubricating system metering valves – the valves that dispense oil or grease in controlled proportions to each connected lube point – which are constructed of zinc- or nickel-plated carbon steel.

“In such an environment, the corrosion resistant life of a plated carbon steel metering valve or system component will only be weeks to months,” Hanley says. “Although the initial corrosion will look much like rust, it will eventually cause the lubrication metering valve to lose its effectiveness long before normal wear and tear would compromise that part.”

In the food processing industry, corrosion problems are normally prevented through the use of equipment made of stainless steel. However, as a broad offering of stainless steel metering valves has not been readily unavailable, the only effective anti-corrosion solution for automatic lubrication system components has been to enclose the plated carbon steel metering valves into stainless steel enclosures. Including the cost of the enclosure, the bulkhead fittings, and the installation labor, it is easy to spend $2,000 to protect a $500 plated carbon steel metering valve. Yet, the space required to mount such as enclosure may not be available on or near the processing line.

In such cases the installation metering devices made of stainless steel that can be mounted directly to the plant equipment is the most cost effective solution to maintaining sanitary standards and insuring long-term production reliability. Typically, stainless steel metering valves such as those offered by Lubrication Scientifics cost between 1-1/2 and 3 times the price of a carbon steel-plated metering valve. Still, this is typically 40% to 60% less expensive than enclosing plated carbon steel valves in a stainless steel enclosure.

Lubrication part of automated system basics

There are several different types of automated lubrication systems, but a typical system consists of controller/timer, pump with reservoir, supply line, metering valves and feed lines.

Whatever the design, automated lubrication system metering valves must stand up to the rigors of harsh plant environments.

One of the most common lubrication systems is the Single-Line Parallel, which is also referred to as the Injector-type of lubrication delivery methodology. This system is known for its ease of installation, adjustable metering of valves (or injectors) and applicability to a minimum of one and maximum of six lube points per device. Lubrication points may be added or removed without redesign of the system. On the down side, it is difficult to verify that each lubrication point is constantly being serviced.

Another common system is the Dual-Line Parallel. This system is also easy to install and features adjustable metering valves. With this type of system a minimum of one and maximum of eight lube points may be serviced from each device, and lubrication points may be added or subtracted without system redesign. Also, heavy greases may be delivered over very long distances. However, with this system it is difficult to verify that each lubrication point is constantly being serviced.

A third type of automated system, the Single-Line Progressive System (aka the Divider Valve System), is precisely engineered to deliver exact lubricant requirements to each point. However, with this system lubrication amounts and points may not be altered, and initial installation costs are higher than with other systems. A primary advantage of these systems is that system performance can be easily and inexpensively monitored to verify that each lube point is constantly being serviced.

In order to overcome the various threats of corrosive and caustic environments, Lubrication Scientifics makes all three types of system and components available in 303 and 316 stainless steel, most of which are available within days rather than months.

Verifiable system advantages

Plants that have the verifiable automated system normally have the need to deliver precise amounts of lubrication to many points.

The biggest advantage of the Single-Line Progressive type of system is that every lubrication point is monitored, ensuring that each point is receiving the proper lubrication, thereby maximizing production uptime.

In addition, this type of system prevents unauthorized interference with system settings, so that workers cannot inadvertently change the precise amounts and intervals of lubrication sent to various points.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site