The CM-1000 for cooling water pumps can be pre-installed in new ships or installed while underway

Colfax Fluid Handling is exhibiting two advanced developments for marine applications at SMM in hall A2 stand 219. These are the MI-D centrifugal pump with a capacity of up to 3.900 m3/h and delivery head of up to 50m and the turnkey version of the CM-1000 electronic pump controller for use in control cabinets. The MI-D pumps seawater and fresh water for cooling and ballast systems. The CM-1000 for cooling water pumps can be pre-installed in new ships or installed while underway and brought into service without downtime.

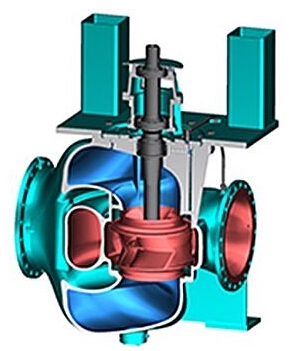

The six new sizes of the Allmarine MI-D series cover the needs of ships ranging from about 60,000 dwt to more than 200,000 dwt. Shipowners receive numerous benefits from the patented characteristics of the double-suction, symmetrical design with just one shaft seal, no internal bearings, and corrosion resistant materials. "The MI-D is probably the lightest and smallest water pump for large flow rates yet it also has an outstanding service life and extraordinary efficiency in marine applications," according to Christian Martin, director of product management. Efficiency is greater than 80 per cent and the pumps are maintenance free between service intervals. Their NPSH values of below 4m make these pumps ideal for ballast systems. Four-pole motors reduce space needs and procurement costs compared to six-pole motors.

CM-1000 controls the flow of cooling seawater pumps according to the temperature of the fresh water and current cooling requirements, thereby saving considerable amounts of electricity. Condition monitoring keeps track of leaks, vibrations, and bearing temperature, so downtime is reduced.

The new turnkey version provides the full electronics as a cabinet solution, including frequency converters. These modules need only to be wired into the ship. When the ship is at a standstill or slow steaming in a cold environment, CM-1000 now shuts down the pumps completely (All-off) and switches them back on automatically as required, which also greatly reduces energy consumption. Finally, cooler clogging supervision monitors cooler status and supports the crew during planning and servicing of the cooling system.

The CM-1000 for cooling water pumps can be pre-installed in new ships or installed while underway

Colfax Fluid Handling is exhibiting two advanced developments for marine applications at SMM in hall A2 stand 219. These are the MI-D centrifugal pump with a capacity of up to 3.900 m3/h and delivery head of up to 50m and the turnkey version of the CM-1000 electronic pump controller for use in control cabinets. The MI-D pumps seawater and fresh water for cooling and ballast systems. The CM-1000 for cooling water pumps can be pre-installed in new ships or installed while underway and brought into service without downtime.

The six new sizes of the Allmarine MI-D series cover the needs of ships ranging from about 60,000 dwt to more than 200,000 dwt. Shipowners receive numerous benefits from the patented characteristics of the double-suction, symmetrical design with just one shaft seal, no internal bearings, and corrosion resistant materials. "The MI-D is probably the lightest and smallest water pump for large flow rates yet it also has an outstanding service life and extraordinary efficiency in marine applications," according to Christian Martin, director of product management. Efficiency is greater than 80 per cent and the pumps are maintenance free between service intervals. Their NPSH values of below 4m make these pumps ideal for ballast systems. Four-pole motors reduce space needs and procurement costs compared to six-pole motors.

CM-1000 controls the flow of cooling seawater pumps according to the temperature of the fresh water and current cooling requirements, thereby saving considerable amounts of electricity. Condition monitoring keeps track of leaks, vibrations, and bearing temperature, so downtime is reduced.

The new turnkey version provides the full electronics as a cabinet solution, including frequency converters. These modules need only to be wired into the ship. When the ship is at a standstill or slow steaming in a cold environment, CM-1000 now shuts down the pumps completely (All-off) and switches them back on automatically as required, which also greatly reduces energy consumption. Finally, cooler clogging supervision monitors cooler status and supports the crew during planning and servicing of the cooling system.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site