Contributing to Improved Automobile Fuel Efficiency and Reliability

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a bearing with solid lubricant film for various transmissions (T/M) such as automobile automatic transmissions (AT) and continuously variable transmissions (CVT). This product contributes to higher automobile reliability by reducing wear due to creep, a phenomenon where the outer ring of the bearing starts to shift in transmission cases (housing). NSK is targeting 2 billion yen in global annual sales of this product in 2020.

Development Background

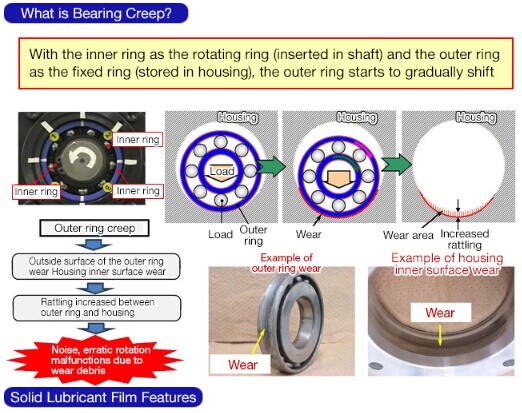

In recent years, demands for more compact, lightweight T/M such as AT and CVT have become more strict with the need to improve automobile fuel efficiency, resulting in thinner T/M housings and bearings. Due to this thinness, with time, the housing can slightly deform, leaving a gap between the housing and bearing, which in turn can cause the outer ring of the bearing to lose its shape. This leads to creep, a phenomenon where the outer ring starts to very gradually rotate when it should not. Creep eventually causes housing wear.

Housing wear due to creep amplifies T/M vibration, resulting in improper rotation and creating wear debris which adversely affects the functionality of parts within the T/M, thereby reducing automobile reliability and comfort.

Preventing creep generally involves mechanically attaching the bearing to the housing, installing an O-ring, and thickening the outer ring. These measures, however, are costly, require parts to be larger, and make it more difficult to assemble the bearings.

To solve these issues, NSK set out to develop a product that would not cause housing wear even if some creep occurred.

Product Features

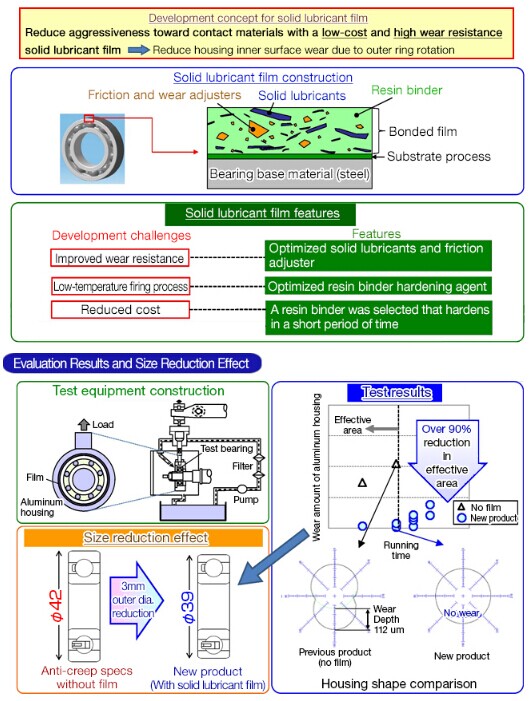

This product includes a low-friction, solid lubrication film coating on the outside surface of the outer ring, lowering the friction coefficient to reduce housing wear even if the fixed outer ring starts to creep. Since simply coating the outside surface of the outer ring can prevent wear, there is no need to increase bearing size or change the construction of the bearing periphery, thus maintaining ease of assembly.

The solid lubricant film consists of a processed substrate on the surface of the bearing base material and a bonded film coating on the substrate (resin binder, solid lubricants, friction and wear adjusters). Solid lubricant film is typically used on products other than bearings such as gears and valves, but applying it to bearings posed challenges such as wear resistance (peeling), high-temperature firing processes which reduced performance of bearing base materials, and higher costs. This product solves all of these issues with the following features.

1. Improved wear resistance (anti-peeling)

NSK optimized the construction of the friction and wear adjusters and solid lubricant agent, as well as the adjuster's grain size. The resulting adjuster construction resists wear even in harsh environments and maintains wear resistance for long periods of time.

2. Low-temperature firing process

When hardening the bonded film, the bearing steel, which serves as the base material, could lose hardness under continuous high temperatures, which would reduce bearing performance in areas such as durability. To avoid this, NSK created an optimized resin binder hardener to allow the bonded film to be hardened at lower temperatures.

3. Reduced cost

NSK selected a resin binder that hardens in a short period of time for the hardening process after applying the bonded film, lowering overall costs.

Product Benefits

This product eliminates the need to make bearing dimensions larger, prevents T/M housing wear due to creep, and contributes to better automobile fuel efficiency and reliability.

Contributing to Improved Automobile Fuel Efficiency and Reliability

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a bearing with solid lubricant film for various transmissions (T/M) such as automobile automatic transmissions (AT) and continuously variable transmissions (CVT). This product contributes to higher automobile reliability by reducing wear due to creep, a phenomenon where the outer ring of the bearing starts to shift in transmission cases (housing). NSK is targeting 2 billion yen in global annual sales of this product in 2020.

Development Background

In recent years, demands for more compact, lightweight T/M such as AT and CVT have become more strict with the need to improve automobile fuel efficiency, resulting in thinner T/M housings and bearings. Due to this thinness, with time, the housing can slightly deform, leaving a gap between the housing and bearing, which in turn can cause the outer ring of the bearing to lose its shape. This leads to creep, a phenomenon where the outer ring starts to very gradually rotate when it should not. Creep eventually causes housing wear.

Housing wear due to creep amplifies T/M vibration, resulting in improper rotation and creating wear debris which adversely affects the functionality of parts within the T/M, thereby reducing automobile reliability and comfort.

Preventing creep generally involves mechanically attaching the bearing to the housing, installing an O-ring, and thickening the outer ring. These measures, however, are costly, require parts to be larger, and make it more difficult to assemble the bearings.

To solve these issues, NSK set out to develop a product that would not cause housing wear even if some creep occurred.

Product Features

This product includes a low-friction, solid lubrication film coating on the outside surface of the outer ring, lowering the friction coefficient to reduce housing wear even if the fixed outer ring starts to creep. Since simply coating the outside surface of the outer ring can prevent wear, there is no need to increase bearing size or change the construction of the bearing periphery, thus maintaining ease of assembly.

The solid lubricant film consists of a processed substrate on the surface of the bearing base material and a bonded film coating on the substrate (resin binder, solid lubricants, friction and wear adjusters). Solid lubricant film is typically used on products other than bearings such as gears and valves, but applying it to bearings posed challenges such as wear resistance (peeling), high-temperature firing processes which reduced performance of bearing base materials, and higher costs. This product solves all of these issues with the following features.

1. Improved wear resistance (anti-peeling)

NSK optimized the construction of the friction and wear adjusters and solid lubricant agent, as well as the adjuster's grain size. The resulting adjuster construction resists wear even in harsh environments and maintains wear resistance for long periods of time.

2. Low-temperature firing process

When hardening the bonded film, the bearing steel, which serves as the base material, could lose hardness under continuous high temperatures, which would reduce bearing performance in areas such as durability. To avoid this, NSK created an optimized resin binder hardener to allow the bonded film to be hardened at lower temperatures.

3. Reduced cost

NSK selected a resin binder that hardens in a short period of time for the hardening process after applying the bonded film, lowering overall costs.

Product Benefits

This product eliminates the need to make bearing dimensions larger, prevents T/M housing wear due to creep, and contributes to better automobile fuel efficiency and reliability.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site