As journal bearings have proven their advantages in several other heavy industries, Winergy started to develop the technology as an alternative to common roller bearings in 2010.

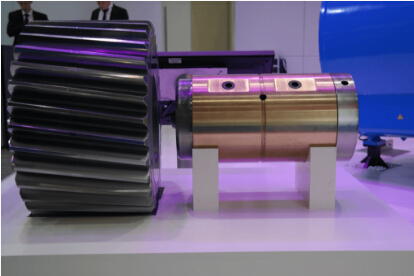

By introducing journal bearings into its gearboxes Winergy says it sets another milestone for wind turbine drive technology. Bearings are the critical wear parts of wind gearboxes because they are exposed to high loads in operation and therefore have a significant impact on the overall gearbox reliability. As journal bearings have proven their advantages in several other heavy industries, Winergy started to develop the technology as an alternative to common roller bearings in 2010.

Journal bearings deliver:

Nearly no wear

Reduced noise and vibrations

Higher efficiency at lower costs

Since March 2013 a 2 MW gearbox prototype with journal bearings has been in operation in a Vestas V90 turbine in Sweden. After the testing period of two and a half years the bearings performed as expected: They show no wear in operation and idling and run 100% reliable. Due to these results and the proven advantages, the wind industry shows great interest in the journal bearing technology. Throughout 2016 and 2017 Winergy will deliver additional gearbox prototypes with journal bearings to major customers.

The journal bearing technology is available in Winergy gearboxes and for the HybridDrive.

As journal bearings have proven their advantages in several other heavy industries, Winergy started to develop the technology as an alternative to common roller bearings in 2010.

By introducing journal bearings into its gearboxes Winergy says it sets another milestone for wind turbine drive technology. Bearings are the critical wear parts of wind gearboxes because they are exposed to high loads in operation and therefore have a significant impact on the overall gearbox reliability. As journal bearings have proven their advantages in several other heavy industries, Winergy started to develop the technology as an alternative to common roller bearings in 2010.

Journal bearings deliver:

Nearly no wear

Reduced noise and vibrations

Higher efficiency at lower costs

Since March 2013 a 2 MW gearbox prototype with journal bearings has been in operation in a Vestas V90 turbine in Sweden. After the testing period of two and a half years the bearings performed as expected: They show no wear in operation and idling and run 100% reliable. Due to these results and the proven advantages, the wind industry shows great interest in the journal bearing technology. Throughout 2016 and 2017 Winergy will deliver additional gearbox prototypes with journal bearings to major customers.

The journal bearing technology is available in Winergy gearboxes and for the HybridDrive.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site