Federal-Mogul Powertrain, a division of Federal-Mogul Holdings Corporation has enhanced its line of ThermFlex exhaust insulating sleeves. The textile heat shield’s optimized design can now be tailored to fit almost any combination of exhaust pipe and tube geometries, helping to increase the efficiency of a vehicle exhaust system while protecting nearby sensitive components. Additionally, Federal-Mogul Powertrain’s unique flexible manufacturing process produces an exhaust sleeve that is application-specific without the need for custom tooling.

A knitted sleeve typically produced from inorganic fibres such as fiberglass, basalt and silica, ThermFlex traps heat within the exhaust system, benefitting both systems protection and emissions control. Federal-Mogul Powertrain has developed a family of different fabrics, with a specification of withstanding temperatures up to 1100 °C. In the future, even temperatures up to 1800 °C could be contained, depending on the materials used.

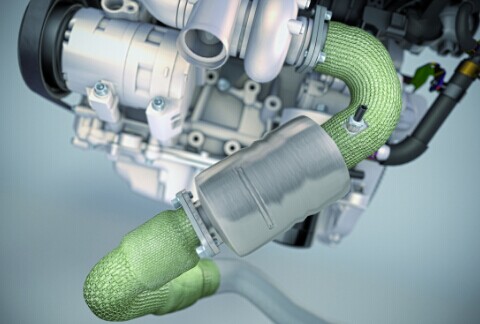

ThermFlex can expand to twice its original diameter to accommodate the flanges and bends typically seen on exhaust system components. Click to enlarge.

The innovative product design allows the sleeve diameter to expand to up to twice its original size and can accommodate the flanges and bends common on exhaust system components, while the construction can be specified to include vents to strategically direct heat away from sensitive components. Customized built-in bracket spaces to ease installation while maintaining the integrity of the sleeving structure are also an option.

Depending on the layout and requirements, ThermFlex sleeves can reduce mass by 40-60 percent compared to conventional rigid heat shields and installation is rapid, typically less than five seconds for a length up to 500 mm.

Federal-Mogul uses proprietary computerized knitting technology to enable rapid prototyping of ThermFlex sleeves, cutting the lead time to production and eliminating tooling costs. During the knitting process, one continuous yarn is used with a specific needle stitch to create the unique knit structures. Several continuous yarns can be used to add further properties. Prototypes are modelled on the customer part and adjusted to ensure proper alignment. The entire prototype manufacturing phase takes just one to two weeks.

ThermFlex products are sold under the Bentley-Harris and Federal-Mogul brand names.

Federal-Mogul Powertrain, a division of Federal-Mogul Holdings Corporation has enhanced its line of ThermFlex exhaust insulating sleeves. The textile heat shield’s optimized design can now be tailored to fit almost any combination of exhaust pipe and tube geometries, helping to increase the efficiency of a vehicle exhaust system while protecting nearby sensitive components. Additionally, Federal-Mogul Powertrain’s unique flexible manufacturing process produces an exhaust sleeve that is application-specific without the need for custom tooling.

A knitted sleeve typically produced from inorganic fibres such as fiberglass, basalt and silica, ThermFlex traps heat within the exhaust system, benefitting both systems protection and emissions control. Federal-Mogul Powertrain has developed a family of different fabrics, with a specification of withstanding temperatures up to 1100 °C. In the future, even temperatures up to 1800 °C could be contained, depending on the materials used.

ThermFlex can expand to twice its original diameter to accommodate the flanges and bends typically seen on exhaust system components. Click to enlarge.

The innovative product design allows the sleeve diameter to expand to up to twice its original size and can accommodate the flanges and bends common on exhaust system components, while the construction can be specified to include vents to strategically direct heat away from sensitive components. Customized built-in bracket spaces to ease installation while maintaining the integrity of the sleeving structure are also an option.

Depending on the layout and requirements, ThermFlex sleeves can reduce mass by 40-60 percent compared to conventional rigid heat shields and installation is rapid, typically less than five seconds for a length up to 500 mm.

Federal-Mogul uses proprietary computerized knitting technology to enable rapid prototyping of ThermFlex sleeves, cutting the lead time to production and eliminating tooling costs. During the knitting process, one continuous yarn is used with a specific needle stitch to create the unique knit structures. Several continuous yarns can be used to add further properties. Prototypes are modelled on the customer part and adjusted to ensure proper alignment. The entire prototype manufacturing phase takes just one to two weeks.

ThermFlex products are sold under the Bentley-Harris and Federal-Mogul brand names.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site