Federal-Mogul Powertrain, a division of Federal-Mogul Holdings Corporation, designs, develops and manufactures mechanical face seals that are the product of choice to protect precision assemblies from the harsh environments and hostile debris experienced in industries such as mining. Unlike lip seals, in which an elastomer lip rubs against a hard steel shaft, face seals provide a metal-to-metal mechanical seal that is highly resistant to wear and the ingress of abrasive particles. This makes them ideal for use in a wide range of applications, including off-highway trucks; construction machinery, tunnelling machines; and rock crushers.

Federal-Mogul Powertrain’s most recent face seal development is the HSL seal, an evolution and special form of the company’s well-proven square bore seal. “The HSL seal uses a unique and patented design for the elastomeric part of the seal with an integral dirt exclusion lip and heavy-duty spin protection. These features improve protection significantly, leading to reduced leakage, extended service life and resisting compression from dried mud that could otherwise result in subsequent leakage when the seal has to follow movements.”

Federal-Mogul Powertrain says it has been developing and manufacturing mechanical face seals for more than 60 years. The company’s product engineering and application engineering functions are integrated in a single group to provide maximum support to customers and ensure the optimum solution is produced for each case; whether an adaption of an existing product or a unique design.

“Compared to automotive seals, large face seals are a niche product, with order quantities as low as ten units, but they are used in applications where the financial consequences of downtime for repair are very significant,” said Andreas Dengler, Manager Application Engineering and Product Development, Federal-Mogul Powertrain. “Our mechanical face seals are widely acknowledged as delivering the utmost reliability and durability in service demanded by the likes of the agriculture, mining and construction industries.”

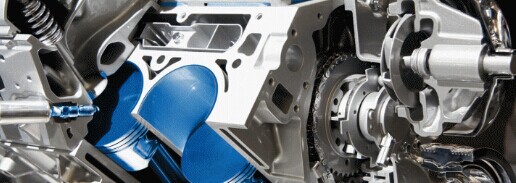

A face seal consists of two metal rings, one stationary and the other rotating, each backed by an elastomeric ring that pushes the faces together. A controlled force is exerted by confining the elastomers within a defined space in their respective housings. Because all the relative movement occurs at the contact between the metal rings, the elastomers are only required to provide a static seal, which does not wear. The resilience of the elastomer elements makes the design highly robust and able to accept fluctuations in pressure, radial shaft movement and dimensional changes due to progressive wear of the metal faces.

“Compared to the thin rubber edge of a lip seal, the sealing faces of a mechanical face seal are very hard and have a broader area of contact,” explained Gian Maria Olivetti, Chief Technology Officer, Federal-Mogul Powertrain. “Both these factors increase the wear resistance and robustness of the seal, delivering longer operational life and greater reliability in the very difficult environments typical of off-highway heavy applications such as big dumpers and construction or agricultural equipment.”

“Successful development of face seal technology brings together a number of disciplines, requiring an understanding of tribology, elastomers and the factors specific to the application, such as pressure, misalignment and contamination. In use, the topography of the sealing faces changes over time, in a process called tribomutation, as mixed lubrication conditions influence the wear of the surfaces. This requires consistent bulk material properties to ensure uniform characteristics over the life of the seal. A number of specialised seal ring materials have been developed by Federal-Mogul Powertrain to provide the necessary resistance to wear, seizure, scoring and corrosion. They include pearlitic, and ledeburitic cast irons. These contain various forms of graphite which contributes to good heat transfer and consistent running properties and wear resistance.”

“Extensive experience has allowed Federal-Mogul Powertrain to develop a robust analytical tool for face seal design that enables the company to evaluate new seal geometries or resolve pre-existing customer issues through simulation. The virtual study is then validated using a range of laboratory and rig tests including pre-load, spring characteristics, temperature and wear, supplemented by any special requirements, such as long term and ‘mud box’ testing.”

Federal-Mogul Powertrain produces face seals at its Friedberg site under the well-known GOETZE® brand, in diameters ranging from 51 mm to 1,425 mm. “The Friedberg plant is the only production facility in the world capable of manufacturing casted mechanical face seals larger than 1,000 mm in serial production. As recently as 2013, manufacturing capacities for face seals were extended by 60% to meet increased demand.”

Federal-Mogul Powertrain, a division of Federal-Mogul Holdings Corporation, designs, develops and manufactures mechanical face seals that are the product of choice to protect precision assemblies from the harsh environments and hostile debris experienced in industries such as mining. Unlike lip seals, in which an elastomer lip rubs against a hard steel shaft, face seals provide a metal-to-metal mechanical seal that is highly resistant to wear and the ingress of abrasive particles. This makes them ideal for use in a wide range of applications, including off-highway trucks; construction machinery, tunnelling machines; and rock crushers.

Federal-Mogul Powertrain’s most recent face seal development is the HSL seal, an evolution and special form of the company’s well-proven square bore seal. “The HSL seal uses a unique and patented design for the elastomeric part of the seal with an integral dirt exclusion lip and heavy-duty spin protection. These features improve protection significantly, leading to reduced leakage, extended service life and resisting compression from dried mud that could otherwise result in subsequent leakage when the seal has to follow movements.”

Federal-Mogul Powertrain says it has been developing and manufacturing mechanical face seals for more than 60 years. The company’s product engineering and application engineering functions are integrated in a single group to provide maximum support to customers and ensure the optimum solution is produced for each case; whether an adaption of an existing product or a unique design.

“Compared to automotive seals, large face seals are a niche product, with order quantities as low as ten units, but they are used in applications where the financial consequences of downtime for repair are very significant,” said Andreas Dengler, Manager Application Engineering and Product Development, Federal-Mogul Powertrain. “Our mechanical face seals are widely acknowledged as delivering the utmost reliability and durability in service demanded by the likes of the agriculture, mining and construction industries.”

A face seal consists of two metal rings, one stationary and the other rotating, each backed by an elastomeric ring that pushes the faces together. A controlled force is exerted by confining the elastomers within a defined space in their respective housings. Because all the relative movement occurs at the contact between the metal rings, the elastomers are only required to provide a static seal, which does not wear. The resilience of the elastomer elements makes the design highly robust and able to accept fluctuations in pressure, radial shaft movement and dimensional changes due to progressive wear of the metal faces.

“Compared to the thin rubber edge of a lip seal, the sealing faces of a mechanical face seal are very hard and have a broader area of contact,” explained Gian Maria Olivetti, Chief Technology Officer, Federal-Mogul Powertrain. “Both these factors increase the wear resistance and robustness of the seal, delivering longer operational life and greater reliability in the very difficult environments typical of off-highway heavy applications such as big dumpers and construction or agricultural equipment.”

“Successful development of face seal technology brings together a number of disciplines, requiring an understanding of tribology, elastomers and the factors specific to the application, such as pressure, misalignment and contamination. In use, the topography of the sealing faces changes over time, in a process called tribomutation, as mixed lubrication conditions influence the wear of the surfaces. This requires consistent bulk material properties to ensure uniform characteristics over the life of the seal. A number of specialised seal ring materials have been developed by Federal-Mogul Powertrain to provide the necessary resistance to wear, seizure, scoring and corrosion. They include pearlitic, and ledeburitic cast irons. These contain various forms of graphite which contributes to good heat transfer and consistent running properties and wear resistance.”

“Extensive experience has allowed Federal-Mogul Powertrain to develop a robust analytical tool for face seal design that enables the company to evaluate new seal geometries or resolve pre-existing customer issues through simulation. The virtual study is then validated using a range of laboratory and rig tests including pre-load, spring characteristics, temperature and wear, supplemented by any special requirements, such as long term and ‘mud box’ testing.”

Federal-Mogul Powertrain produces face seals at its Friedberg site under the well-known GOETZE® brand, in diameters ranging from 51 mm to 1,425 mm. “The Friedberg plant is the only production facility in the world capable of manufacturing casted mechanical face seals larger than 1,000 mm in serial production. As recently as 2013, manufacturing capacities for face seals were extended by 60% to meet increased demand.”

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.cjcpx.com www.wfbearings.com

Mobile Site

Mobile Site